[ad_1]

Researchers in South Korea have created a exceptional first-ever encodable multifunctional materials, which may be shifted into completely different shapes and mechanical properties in real-time. The inspiration for this new metamaterial got here from an unlikely place: octopuses.

Based on the researchers, this materials surpasses the bounds of present supplies and opens new potentialities for numerous fields that require fast adaptability, particularly inside robotics.

Overcoming the exhausting limits of sentimental machines

When in comparison with organic examples, soft machines are inclined to fall behind when it comes to their potential to adapt to continuously altering environment. It is because there are important limitations with their real-time tunability, in addition to restrictions on the vary of their reprogrammable properties and functionalities. That’s, till now.

The brand new digitally programmable materials has a number of exceptional mechanical capabilities, together with shape-shifting and reminiscence, stress-strain responses, and Poisson’s ratio (which reveals how the cross-section of a deformable physique modifications below lengthwise stretching) below compression load.

As well as, the brand new materials demonstrates application-oriented functionalities, akin to tunable and reusable vitality absorption and strain supply.

The breakthrough could usher in a brand new age of growth for totally adaptive soft robots and sensible interactive machines.

“We launched a metamaterial composite system that enables for gradational and reversible changes in numerous mechanical data by translating encoded digital sample data into discrete stiffness states of the mechanical pixels,” the workforce write of their paper.

To develop it, the workforce led by Professor Jiyun Kim within the Division of Supplies Science and Engineering at UNIST, South Korea, launched a brand new strategy utilizing graphical stiffness patterns, which permits for wealthy form reconfigurability of a cloth. This allow them to independently swap between what they consult with because the “digital binary stiffness states” (mainly gentle or inflexible states) of the fabric’s constituent items inside a “easy auxetic” (a construction or materials that has a unfavorable Poisson’s ratio) that featured elliptical voids.

The material, the authors clarify of their paper, achieves “in situ and gradational tunability in numerous mechanical qualities.”

“Now we have developed a metamaterial that may implement desired traits inside minutes, with out the necessity for added {hardware},” Jun Kyu Choe, the primary writer of the research and a pupil on the mixed MS/PhD program of Supplies Science and Engineering at UNIST, stated in a statement.

“This opens up new potentialities for superior adaptive supplies and the long run growth of adaptive robots.”

Choe and colleagues demonstrated the fabric’s potential by means of an “adaptive shock vitality absorbing materials”, which adjusts its properties in response to sudden impacts. The fabric was capable of restrict the chance of injury or damage by minimizing the pressure transmitted to the protected object. Then the workforce turned the fabric right into a “pressure transmission materials”, which delivered pressure at desired places and instances.

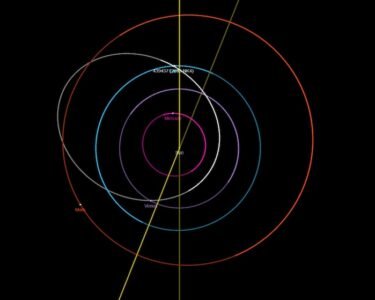

Altering the sample of activated pixels within the materials impacts the way it responds in a ball-drop experiment.

Picture credit score: UNIST (cropped)

By inputting particular digital instructions, the fabric can function adjoining LED switches, which permit exact management over pressure transmission pathways.

The metamaterial can be appropriate with a spread of present gadgets and devices, in addition to artificial intelligence applied sciences, together with deep studying.

“This metamaterial, able to changing digital data into bodily data in real-time, will pave the way in which for modern new supplies that may be taught and adapt to their environment,” added Professor Kim.

The research is revealed in Advanced Materials.